7 Game-Changing Hacks to Supercharge Your Moving Head Light’s Thermal Management

In the dazzling world of stage lighting, moving head lights are the unsung heroes that bring performances to life. However, these powerful luminaires face a constant battle against their greatest enemy: heat. Efficient thermal management is crucial for maintaining optimal performance, extending fixture lifespan, and ensuring show-stopping brilliance night after night. In this illuminating guide, we’ll unveil seven cutting-edge strategies to revolutionize your moving head light’s thermal management system. Get ready to cool down your rig and heat up your shows!

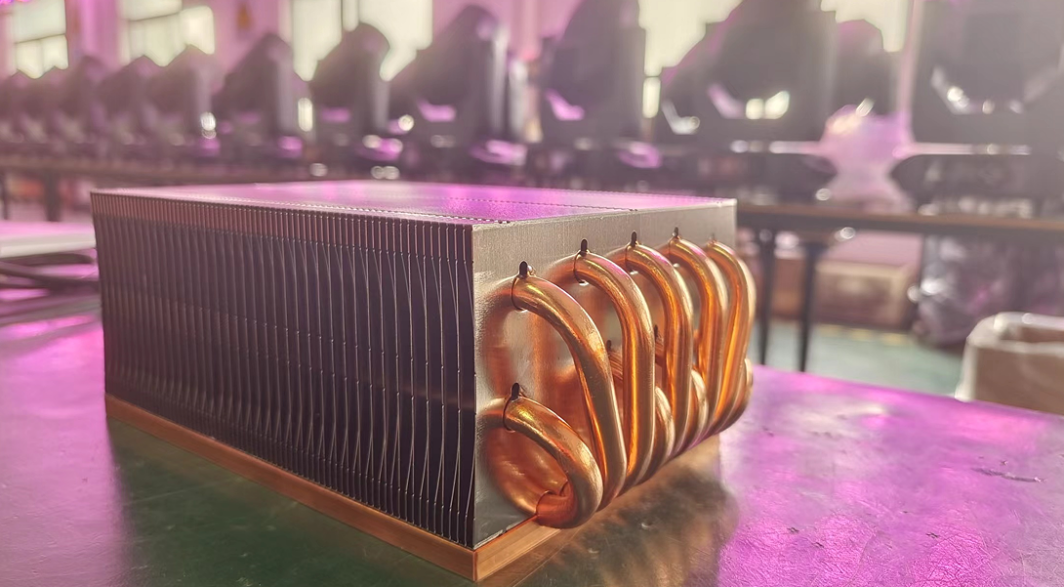

1.Embrace Advanced Heat Sink Designs

The foundation of any effective thermal management system lies in its heat sink. Traditional flat-finned designs are quickly becoming obsolete as innovative solutions emerge.

Key improvements:

- Pin-fin heat sinks: Increase surface area by up to 30%, enhancing heat dissipation

- Skived fin heat sinks: Offer superior thermal conductivity, reducing temperatures by up to 15%

- Phase-change materials (PCMs): Absorb excess heat during operation and release it during cooldown

Pro tip: When selecting a heat sink, consider the thermal conductivity of the material. Copper, with its impressive 401 W/mK conductivity, outperforms aluminum (237 W/mK) but comes at a higher cost and weight.

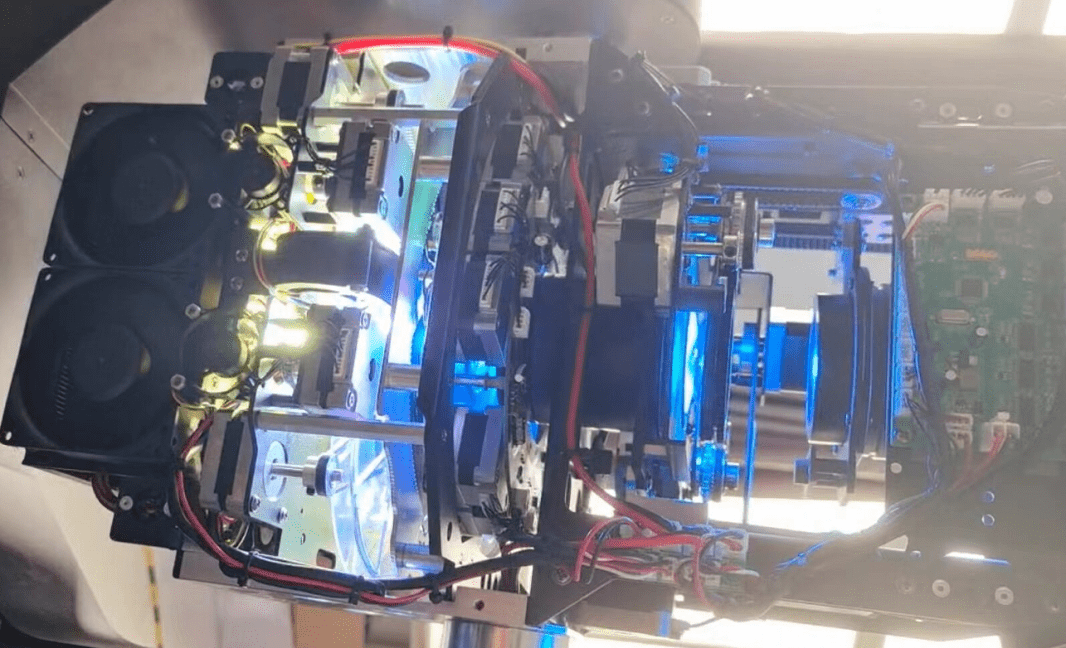

2.Implement Intelligent Fan Control Systems

Gone are the days of constant, noisy fan operation. Smart fan control systems optimize cooling while minimizing noise and energy consumption.

Key features:

- Variable speed control based on real-time temperature monitoring

- Multi-zone cooling for targeted heat management

- Predictive algorithms that anticipate temperature spikes during performances

Case study: The Robe FORTE™ luminaire utilizes an advanced cooling system that adapts fan speeds based on internal temperatures and fixture orientation, resulting in a 20% reduction in overall noise levels.

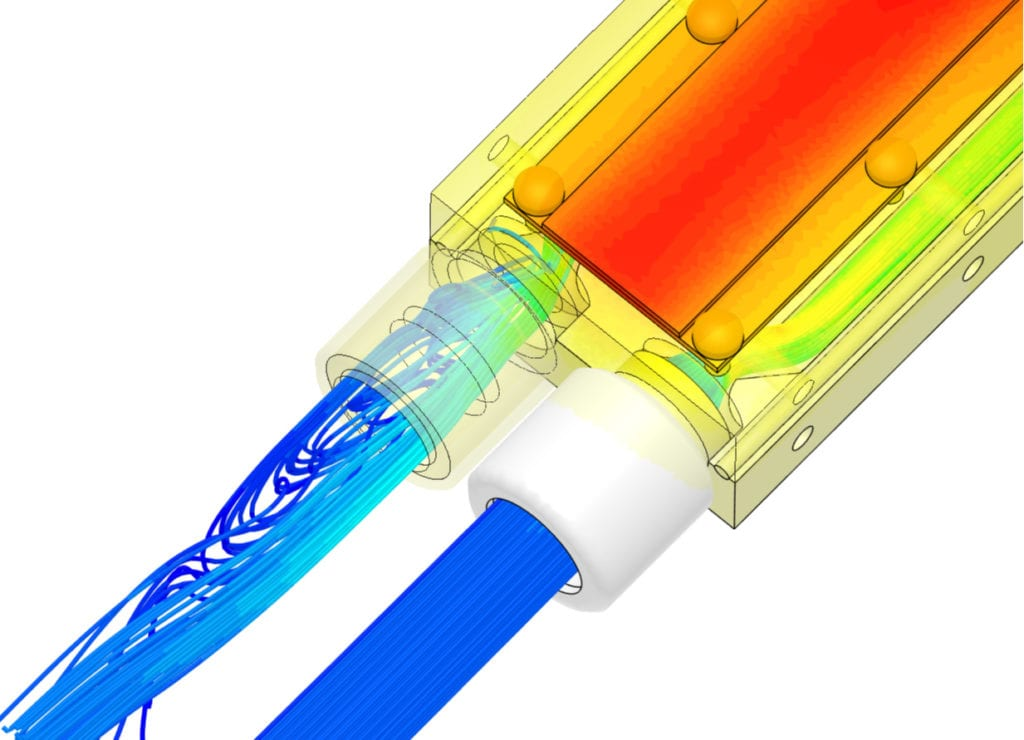

3.Harness the Power of Computational Fluid Dynamics (CFD)

CFD simulations have revolutionized thermal management design, allowing engineers to visualize and optimize airflow within fixtures.

Benefits:

- Identify and eliminate hot spots before prototyping

- Optimize component placement for maximum cooling efficiency

- Reduce development time and costs by up to 50%

Fact: According to a study by the Journal of Light & Visual Environment, CFD-optimized designs can improve overall thermal performance by 15-25% compared to traditional methods.

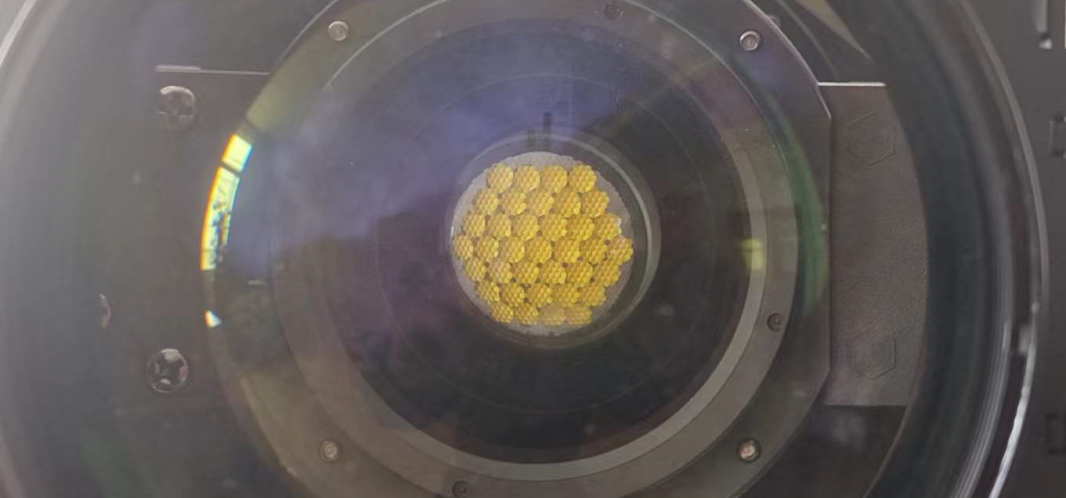

4.Integrate Thermoelectric Cooling (TEC) Modules

For precision cooling of critical components like LEDs and color wheels, thermoelectric cooling offers a compact and efficient solution.

Advantages:

- Spot cooling capabilities for sensitive areas

- No moving parts, increasing reliability

- Reversible operation for heating in cold environments

Industry insight: The latest generation of TEC modules can achieve a temperature differential of up to 70°C, making them ideal for high-power LED cooling applications.

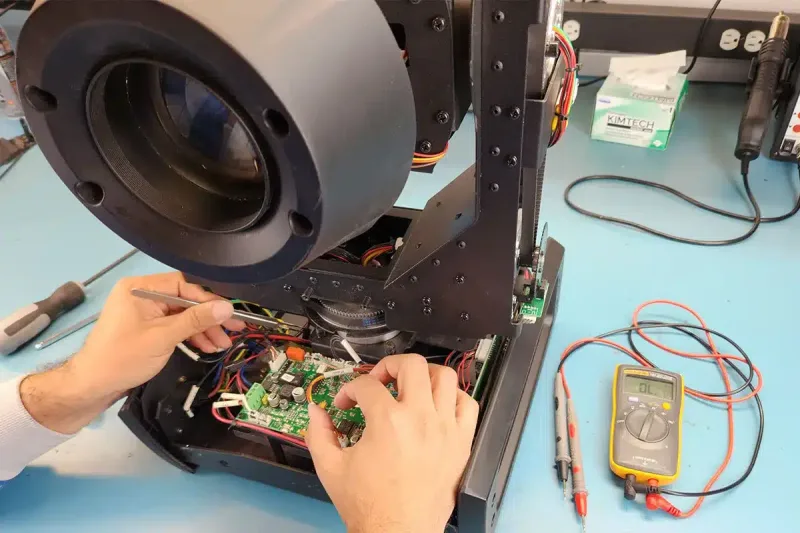

5.Optimize PCB Design for Enhanced Thermal Management

The printed circuit board (PCB) plays a crucial role in heat distribution and dissipation within moving head lights.

Key strategies:

- Utilize thick copper layers (2 oz or higher) for improved heat spreading

- Implement thermal vias to enhance vertical heat transfer

- Design with thermal considerations in mind, placing heat-generating components strategically

Statistic: A well-designed thermal PCB can reduce LED junction temperatures by up to 20°C, potentially doubling the lifespan of the light source.

6.Explore Advanced Materials for Thermal Interface

The interface between heat-generating components and cooling systems is critical for efficient heat transfer.

Cutting-edge options:

- Graphene thermal pads: Offer thermal conductivity up to 1600 W/mK

- Liquid metal thermal interface materials: Provide up to 10 times better performance than traditional thermal pastes

- Carbon nanotube arrays: Achieve near-perfect thermal contact, reducing interface resistance

Expert tip: When selecting thermal interface materials, consider not only thermal conductivity but also long-term stability and ease of application in a production environment.

7.Implement Active Liquid Cooling Systems

For the most demanding applications, liquid cooling systems offer unparalleled thermal management capabilities.

Benefits:

- Up to 4000 times more efficient heat transfer than air cooling

- Silent operation for noise-sensitive environments

- Enables more compact fixture designs by eliminating bulky heat sinks

Real-world example: The High End Systems SolaFrame 3000 utilizes a liquid cooling system to manage its impressive 1000W LED engine, maintaining consistent output and color stability even in challenging environments.

Frequently Asked Questions:

Q: How does improved thermal management affect the lifespan of moving head lights?

A: Effective thermal management can extend the lifespan of LEDs and other components by up to 50%, reducing maintenance costs and improving long-term reliability.

Q: Are liquid cooling systems practical for touring productions?

A: While more complex than traditional air cooling, modern liquid cooling systems are designed for reliability and ease of maintenance, making them viable for touring rigs with proper care and expertise.

Q: How can I determine if my current thermal management system is adequate?

A: Monitor fixture temperatures during operation, check for any performance degradation over time, and consult with manufacturers or lighting experts for specific benchmarks and recommendations.

Q: What’s the impact of ambient temperature on moving head light performance?

A: Higher ambient temperatures can significantly reduce LED output and lifespan. For every 10°C increase in ambient temperature, LED lifespan can decrease by up to 50%.

Q: How often should thermal management systems be maintained?

A: Regular maintenance, including cleaning heat sinks and fans, should be performed at least quarterly. More frequent checks may be necessary in dusty or high-usage environments.

Conclusion:

Mastering the art of thermal management in moving head lights is essential for creating unforgettable lighting experiences. By implementing these seven game-changing strategies, you’ll not only extend the life of your fixtures but also push the boundaries of what’s possible in stage lighting design.

Remember, effective thermal management is an ongoing process that requires attention to detail and a willingness to embrace new technologies. As you apply these techniques to your lighting rigs, you’ll witness firsthand the transformative power of cooler, more efficient moving head lights.

So, are you ready to take your stage lighting to the next level? Implement these thermal management hacks and watch as your productions sizzle without overheating!

Distributor

What is your typical lead time for distributor orders?

Our standard production lead time is 15–30 working days depending on order volume and customization requirements. For stocked models or repeat orders, we can offer shorter delivery times.

How can I apply to become a distributor?

Simply fill out the contact form on this page or email us directly with your company information, market background, and cooperation intention. Our sales team will get in touch with you within 1–2 business days.

What are the advantages of becoming an LQE distributor?

Access to high-performance, patented lighting products

Competitive factory pricing and excellent profit margin potential

Strong R&D capabilities with 80+ national patents

Reliable production capacity: 100,000 units annually

Dedicated account manager to support your growth

1000w

What Is the Warranty Offered by LQE Lighting?

LQE lighting offers a comprehensive 1-year warranty and spare parts on its products, giving customers peace of mind and investment protection.

Can I Have a Sample Order for an LED DJ Light?

Sure, sample order are welcome to test and check LQE quality. Mixed samples are acceptable.

Want to learn more information?

[Reach out to us and receive professional guidance, a personalized quote, and the best solution for your needs.]

Linkedin

YouTube

Whatsapp: +8618924548390

TikTok